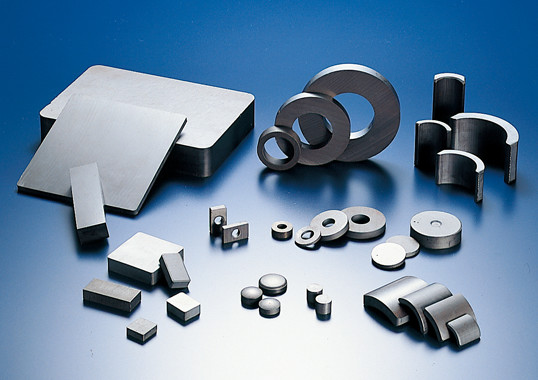

Magna's Magnet

Ferrite Magnet

Ferrite Magnets are Sintered magnets (ceramic magnets) made from ferric oxide, a raw material which is abundant in supply, thus a steady flow of Ferrite magnets can be ensured at a reasonable price setting, in fact the lowest price among competing products in the market today. Due to its high-coercive property, there is a smaller chance of demagnetization, and they are suitable for being used in flat forms. The magnets are produced by pressing a fine-powder of ferric oxide in a mold and heated in a furnace at approximately 1200 degrees Celsius. They are resistant to corrosion and fit for mass production. Ferrite magnets can be classified into two categories: Anisotropic Ferrite and Isotropic Ferrite.

Characteristics

- A steady supply of raw material can be ensured at an inexpensive price-setting.

- High coerciveness makes them less likely to demagnetize.

- Similar to other ceramics ferrite magnets are brittle, but since they are made by molding powdered ferric oxide they are fit for mass production.

- With specific gravity of 4.8g/cm3, these magnets can be much lighter compared to other magnetic products.

- Able to place 2-10 poles on a flat surface. Also possible to magnetize multi-poles along the circumference of the magnet, thus more demands are coming in for applications in meters and motors.

- Used as materials to make rubber magnets and plastic magnets.

Application

Ferrite magnets are used in various products, such as device for electrical instruments, automobile motors and generators, stationery products, household appliances, and healthcare equipments.

Ferrite Magnet Products

Anisotropic Sr-Ferrite Magnet

[Wet type] Made by mixing ferric oxide with a few percent of strontium and also water into a slurry (muddy) state, then poured and pressed in a metal mold. The molding process is done in a magnetic field so the smallest units of the magnet are aligned in a certain direction, making them an Anisotropic Ferrite magnet. After being heated in a furnace, the magnets are abraded and polished into a preferred size and washed for a finishing touch.

[Dry type] Granulated powder of ferric oxide is pressed in a mold, and then heated in a furnace to make this magnet. Its magnetic force is roughly 7% weaker than the wet type, but unlike its counterpart they can have the edges beveled during the molding process.

Isotropic Ba-Ferrite Magnet

A mixture of ferric oxide with a few percent of Barium is powered then granulated before being pressed. The molding is done without a magnetic field and later sintered. The direction of the magnetic force aligns with the magnetic field at the time of magnetization, so the magnetism can be in an axial and/or radial direction. The magnetism itself is about half of that of an Anisotropic Ferrite magnet.

Cap Magnet

By combining Ferrite Magnet with iron yokes, this magnetic product has an enhanced magnetic field by concentrating its magnetic force in a certain direction.

Mirroring Polished

It is a ferrite magnet which made it possible to finish surface with black, deep shine by special processing.