技術力

磁石特性

磁石はその磁気特性と物理特性の違いにより

特徴的な形状があります

使用者にとって重要なのが、磁気特性等による磁石の“形状”です。

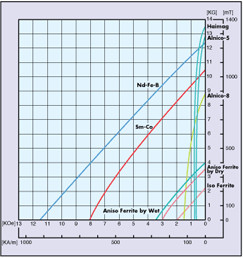

最新の《希土類磁石》は、残留磁束密度Br(吸着力に関係)と保磁力bHc(減磁に関係)がともに最強であるため、他の磁石に比べておもいきった小型化や偏平化が可能となります。

戦前から広く使用されている《アルニコ磁石》は保磁力が小さいため、磁極間(N極から一方磁束密度については希土類と同様に高いので磁石の断面を小さくでき、以上の理由から形状は細長くなります。利点は、温度変化に対する安定性に優れていることです。

《フェライト磁石》は保磁力が大きいので、磁極間を短くできます。ただし磁束密度は低いので、磁石の断面積を大きくする必要があります。したがって形状は偏平なのが特徴です。

磁気特性とその物理特性

代表的磁石

| 磁石の種類 | 希土類 | フェライト | アルニコ | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 項目 | 単位 | ネオジ | サマリウム コバルト |

等方性 | 異方性 ドライ |

異方性 ウェット |

アルニコ-5 | アルニコ-8 | |

| 残留磁束密度Br | kG | 12.4 | 10.5 | 2.2 | 3.6 | 4 | 12.7 | 8.8 | |

| mT | 1,240 | 1,050 | 220 | 360 | 400 | 1,270 | 880 | ||

| 保持力bHc | kOe | 11.6 | 8 | 1.9 | 3 | 3.3 | 0.65 | 1.47 | |

| kA/m | 923 | 636 | 151 | 238 | 262 | 51 | 117 | ||

| 最大エネルギー積 Bhmax |

MGOe | 37 | 24 | 1 | 3 | 3.8 | 5.3 | 5.2 | |

| kJ/m3 | 294.5 | 191 | 8 | 23.9 | 30.2 | 42.2 | 41.4 | ||

| Brの温度特性 | %/℃ | -0.12 | -0.04 | -0.18 | -0.18 | -0.18 | -0.02 | -0.01 | |

| キュリー点 | ℃ | 320 | 750 | 460 | 460 | 460 | 850 | 850 | |

| 密度 | g/cm3 | 7.4 | 8.3 | 4.8 | 4.8 | 4.9 | 7.3 | 7.3 | |

代表的磁石のB-H曲線

希土類

| 項目 | 単位 | ネオジ | サマリウムコバルト |

|---|---|---|---|

| 組成 | ― | Nd2・Fe14・B | Sm2Co17 |

| 成形方法 | ― | 磁界成形 | 磁界成形 |

| 残留磁束密度 Br |

mT | 1210~1270 | 970~1020 |

| kG | 12.1~12.7 | 9.7~1.02 | |

| 保磁力 bHc |

kA/m | 867~979 | 557~836 |

| KOe | 10.9~12.3 | 7~10.5 | |

| 保磁力 iHc |

kA/m | >1353 | 716~1194 |

| KOe | >17 | 9~15 | |

| 最大エネルギ-積 (BH)max |

kJ/m3 | 278~310 | 175~199 |

| MGOe | 35~39 | 22~25 | |

| 温度係数Br | %/K | -0.12 | -0.04 |

| 温度係数iHc | %/K | -0.58 | -0.03 |

| キューリー温度 Tc |

K | 593 | 1093 |

| ℃ | 320 | 820 | |

| リコイル比透磁率 μrec |

― | 1.05 | 1.05 |

| 密度 | g/cm3 | 7.4 | 8.3 |

| 坑折強度 | Mpa | 245 | 118 |

| Kgf/mm2 | 25 | 12 | |

| 圧縮強度 | MPa | 1050 | 500~519 |

| Kgf/mm2 | 107 | 51~53 | |

| 引張強度 | MPa | 44 | 36 |

| Kgf/mm2 | 4.5 | 3.6 | |

| 比熱 | J/(Kg・K) | 0.50×103 | 034×103 |

| cal/g・℃ | 0.12 | 0.08 | |

| 硬度 | HV | 600 | 550 |

| 熱膨張係数 〃 |

ppm/K | 5.5~7.5 | 8 |

| 熱膨張係数 ⊥ |

ppm/K | -3~0.5 | 11 |

| JIS | ― | REFe280/120 | RECo160/70 |

| MMPA | ― | ― | ― |

| 必要着磁磁界 | kA/m | 2400 | 1990 |

| KOe | 30 | 25 | |

| 電気比抵抗 | nΩ・m | 1.3×10-4 | 0.8~0.9 |

フェライト

| 項目 | 単位 | 等方性 | 乾式異方性 | 湿式異方性 |

|---|---|---|---|---|

| 組成 | ― | BaO・6Fe2O3 | SrO・6Fe2O3 | SrO・6Fe2O3 |

| 成形方法 | ― | 乾式成形 | 乾式磁界成形 | 湿式磁界成形 |

| 残留磁束密度 Br |

mT | ≧200 | 310~360 | 380~400 |

| kG | ≧2.0 | 3.1~3.6 | 3.8~4.0 | |

| 保磁力 bHc |

kA/m | 127~159 | 220~250 | 230~275 |

| KOe | 1.6~2.0 | 2.8~3.2 | 2.9~3.5 | |

| 保磁力 iHc |

kA/m | 135~167 | 280~320 | 235~290 |

| KOe | 1.7~2.1 | 3.5~4.0 | 3.0~3.7 | |

| 最大エネルギ-積 (BH)max |

kJ/m3 | 6.3~9.5 | 20~24 | 27~32 |

| MGOe | 0.8~1.2 | 2.5~3.0 | 3.4~4.1 | |

| 温度係数Br | %/K | -0.18 | -0.18 | -0.18 |

| 温度係数iHc | %/K | 0.22 | 0.27~0.42 | 0.27~0.42 |

| キューリー温度 Tc |

K | 723 | 733 | 733 |

| ℃ | 450 | 460 | 460 | |

| リコイル比透磁率 μrec |

― | 1.1~1.2 | 1.1~1.2 | 1.05~1.1 |

| 密度 | g/cm3 | 4.8 | 4.9 | 4.9 |

| 坑折強度 | Mpa | 29~68 | 49~88 | 49~88 |

| Kgf/mm2 | 3~7 | 5~9 | 5~9 | |

| 圧縮強度 | MPa | >686 | >686 | >686 |

| Kgf/mm2 | >70 | >70 | >70 | |

| 引張強度 | MPa | 19~49 | 19~49 | 19~49 |

| Kgf/mm2 | 2~5 | 2~5 | 2~5 | |

| 比熱 | J/(Kg・K) | 0.84×103 | 0.84×103 | 0.84×103 |

| cal/g・℃ | 0.2 | 0.2 | 0.2 | |

| 硬度 | HV | 530 | 530 | 530 |

| 熱膨張係数 〃 |

ppm/K | 9.9 | 11 | 13 |

| 熱膨張係数 ⊥ |

ppm/K | 9.9 | 9 | 8 |

| JIS | ― | MPB-8/15D | MPS-24/24D | MPS-31/24W |

| MMPA | ― | CERAMIC-1 | CERAMIC-6 | CERAMIC-8 |

| 必要着磁磁界 | kA/m | 800 | 800 | 800 |

| KOe | 10 | 10 | 10 | |

| 電気比抵抗 | nΩ・m | >102 | >102 | >102 |

アルニコ

| 項目 | 単位 | アルニコー5 | アルニコー8 | 焼結アルニコ |

|---|---|---|---|---|

| 組成 | ― | 8Al-14Ni-24Co-3Cu-残Fe | 7Al-15Ni-34Co-4Cu-残Fe | 8Al-14Ni-24Co-3Cu-残Fe |

| 成形方法 | ― | 鋳造 | 鋳造 | 湿式磁界成形 |

| 残留磁束密度 Br |

mT | 1250~1300 | 830~900 | 1150 |

| kG | 12.5~13 | 8.3~9.0 | 11.5 | |

| 保磁力 bHc |

kA/m | 47.7~52.5 | 110~123 | 50 |

| KOe | 0.60~0.66 | 1.38~1.55 | 0.63 | |

| 保磁力 iHc |

kA/m | ― | ― | ― |

| KOe | ||||

| 最大エネルギ-積 (BH)max |

kJ/mm3 | 38.2~43.8 | 38.2~43.0 | 37 |

| MGOe | 4.8~5.5 | 4.8~5.4 | 4.6 | |

| 温度係数Br | %/K | -0.02 | -0.02 | -0.02 |

| 温度係数iHc | %/K | ― | ― | ― |

| キューリー温度 Tc |

K | 1123 | 1123 | 1123 |

| ℃ | 850 | 850 | 850 | |

| リコイル比透磁率 μrec | ― | 3.6 | 3.6 | 3.6 |

| 密度 | g/cm3 | 7.3 | 7.3 | 7.1 |

| 坑折強度 | Mpa | 73.5 | 73.5 | 7.35 |

| Kgf/mm2 | 7.5 | 7.5 | 7.5 | |

| 圧縮強度 | MPa | ― | ― | ― |

| Kgf/mm2 | ||||

| 引張強度 | MPa | 37.2 | 37.2 | 37.3 |

| Kgf/mm2 | 3.8 | 3.8 | 3.8 | |

| 比熱 | J/(Kg・K) | ― | ― | ― |

| cal/g・℃ | ||||

| 硬度 | HV | 650 | 650 | 650 |

| 熱膨張係数 〃 |

ppm/K | 11 | 11 | 11 |

| 熱膨張係数 ⊥ |

ppm/K | 11 | 11 | 11 |

| JIS | ― | AlNiCo37/5 | AlNiCo38/11 | AlNiCo S-34/5 |

| MMPA | ― | AlNiCO-5 | AlNiCO-8 | ― |

| 必要着磁磁界 | kA/m | 240 | 640 | 240 |

| KOe | 3.0 | 8.0 | 3.0 | |

| 電気比抵抗 | nΩ・m | 4.7×102 | 4.7×102 | 47×102 |

その他

| 項目 | 単位 | ネオジボンド | ラバー異方性 | ラバー等方性 | |

|---|---|---|---|---|---|

| 組成 | ― | Nd2・Fe14・B | ― | ― | |

| 成形方法 | ― | 圧縮成形 | 射出成形 | 圧延成形 | 圧延成形 |

| 残留磁束密度 Br |

mT | 640~710 | 640~710 | 230 | 1370 |

| kG | 6.4~7.1 | 6.4~7.1 | 2.3 | 1.37 | |

| 保磁力 bHc |

kA/m | 570~760 | 410~620 | 135 | 102 |

| KOe | 5.7~7.6 | 4.1~6.2 | 1.7 | 1.28 | |

| 保磁力 iHc |

kA/m | 370~470 | 250~400 | ― | ― |

| KOe | 4.7~5.9 | 3.1~4.9 | |||

| 最大エネルギ-積 (BH)max |

kJ/m3 | 60~96 | 28~60 | 8.8 | 4.0 |

| MGOe | 7.5~12.0 | 3.5~7.5 | 1.1 | 0.5 | |

| 温度係数Br | %/K | -0.1~-0.15 | -0.1~-0.15 | -0.18~-0.19 | -0.18 |

| 温度係数iHc | %/K | ― | ― | 0.35~0.5 | 0.35 |

| キューリー温度 Tc |

K | ※393 | ※393 | ※353 | ※353 |

| ℃ | ※120 | ※120 | ※80 | ※80 | |

| リコイル比透磁率 μrec |

― | 1.1~1.2 | 1.1~1.2 | 1.03~1.07 | 1.03~1.07 |

| 密度 | g/cm3 | 5.6~6.2 | 4.2~5.5 | 3.7 | 3.7 |

| 坑折強度 | Mpa | 49.0~58.8 | ― | ― | ― |

| Kgf/mm3 | 5.0~6.0 | ||||

| 圧縮強度 | MPa | ― | ― | ― | ― |

| Kgf/mm3 | |||||

| 引張強度 | MPa | ― | 30000 | 666 | 392 |

| Kgf/mm3 | 3061 | 68 | 40 | ||

| 比熱 | J/(Kg・K) | ― | ― | 0.7~0.8×103 | 0.7~0.8×103 |

| cal/g・℃ | 0.167~0.191 | 0.167~0.191 | |||

| 硬度 | HV | 430 | 430 | 760 | 450 |

| 熱膨張係数 〃 |

ppm/K | 13~15 | 50 | ― | ― |

| 熱膨張係数 ⊥ |

ppm/K | 13~15 | 50 | 100~150 | 100~150 |

| JIS | ― | REFe63/64p | REFe63/64p | ― | ― |

| MMPA | ― | ― | ― | ― | ― |

| 必要着磁磁界 | kA/m | 2000 | 2000 | 800 | 800 |

| KOe | 25 | 25 | 10 | 10 | |

| 電気比抵抗 | nΩ・m | 56×103 | 56×103 | ― | ― |